With the rapid rise of middle class, apparel customization is becoming a new trend of consumption. As a result, the garment industry is facing a revolution of switching to flexible production.

Apparel customization is divided into two parts, normal customization and high-end customization. As a report published by newsijie.com, the Chinese apparel customization market is growing with a relatively high speed, estimating to reach a size of 40 billion USD in 2022.

Traditionally, the apparel customization industry relies heavily on the mentorship, which requires years of experience to transform from 2D design drawing to the 3D apparel. The interconversion between 2D and 3D posts extremely high requirement to the technicians and has become a great difficulty during the production of customized apparels.

To optimize the production of customized apparels, RUIZHIWEIDU, an internet-based garment company in Beijing works with SCANTECH iReal COLOR 3D SCANNER, developing a 3D solution for apparel customization. The solution is widely applied to the production of high-end clothing (suit, wedding dress, etc.), special wear, and any other clothing with specific requirements.

Case Analysis

The process of the 3D solution to apparel customization

Step 1: Get an accurate 3D model of the body

3D scanning the customer with SCANTECH iReal high-precision handheld 3D scanner without attaching markers and get the complete 3D body model.

Step 2:Data post-processing

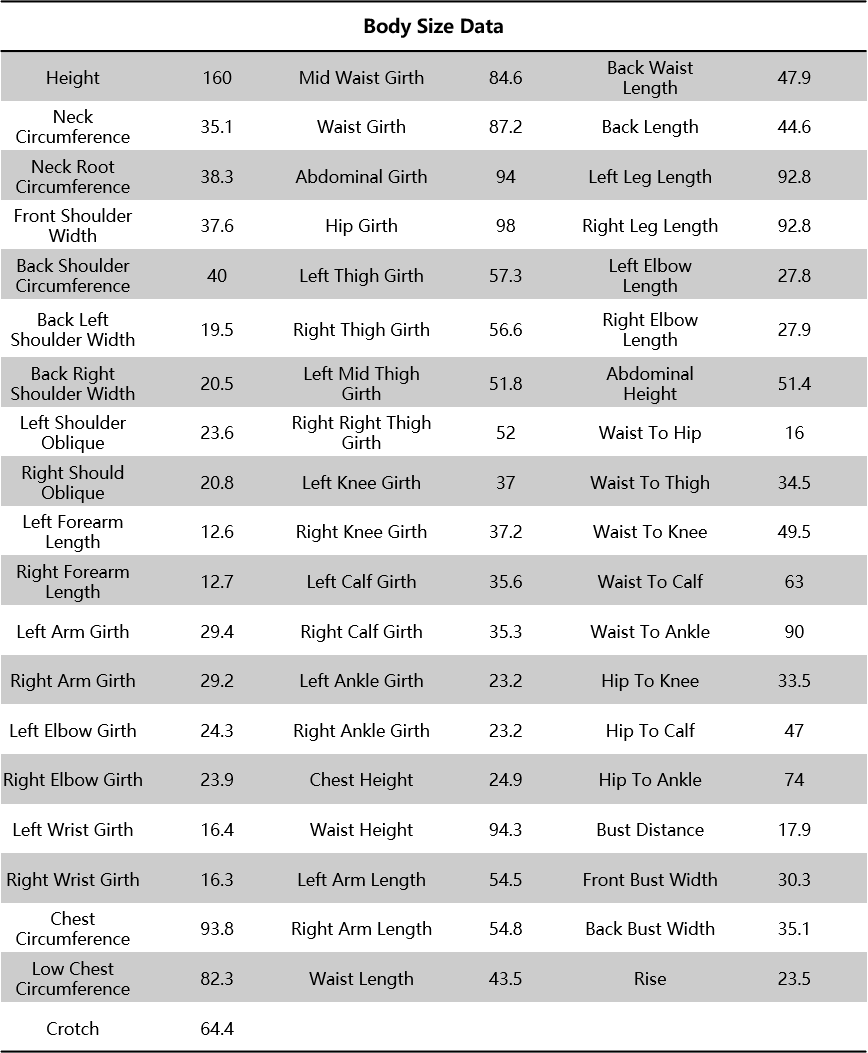

Import the 3D body model into data center for further analysis and calculate 58 key body size data, which are precise, standard and able to connect each stage of production seamlessly.

Body size data

Body size data

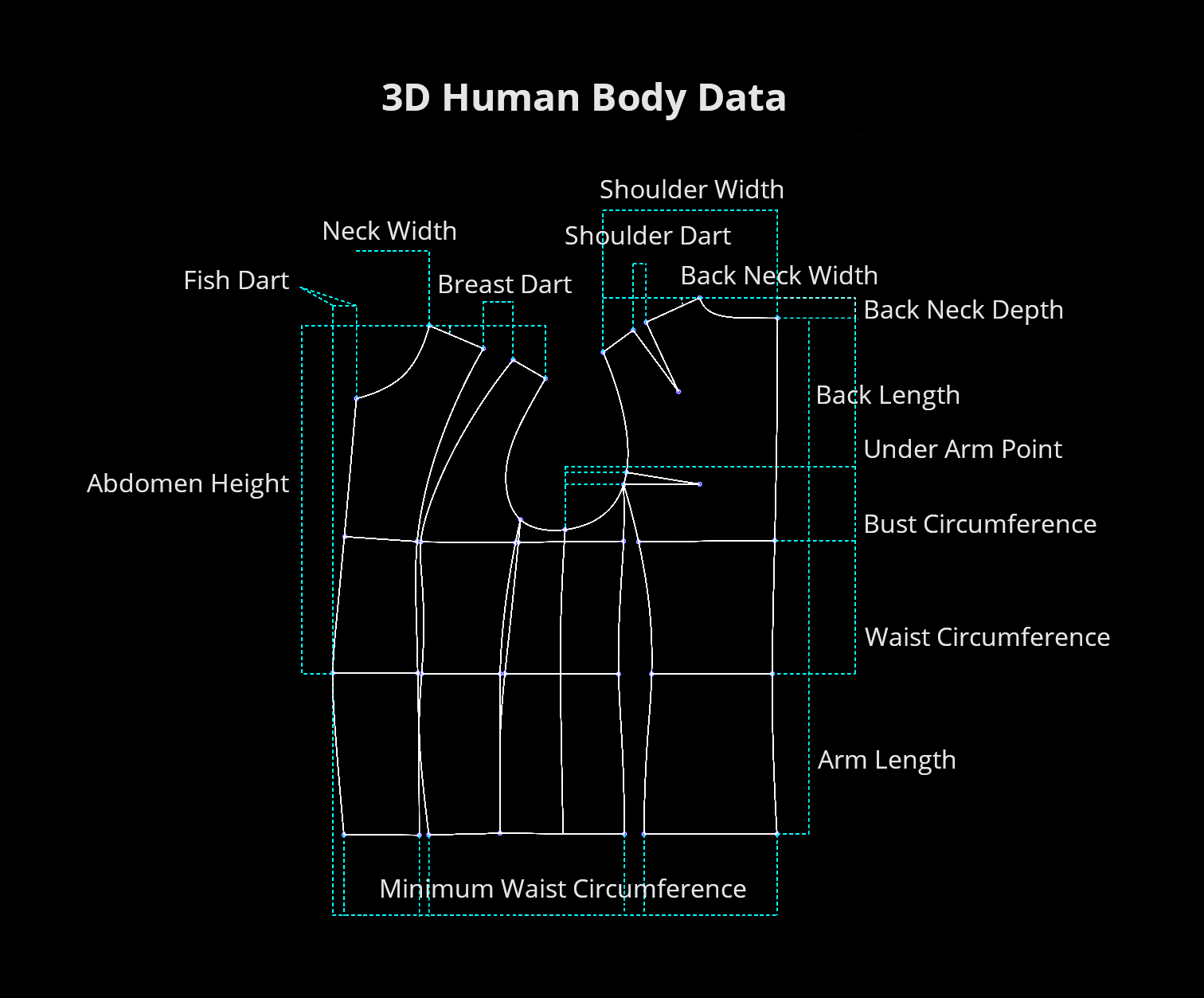

Step 3. Generate 2D data for product development

Import the body model to an intelligent pattern making system. The system applies AI algorithm to generate a scientific, standard, concise pattern for further optimization by the designer.

Personalized pattern based on the body of customer

Personalized pattern based on the body of customer

Step 4. Performance estimation and product development

Involving pattern data along with digital fabric to proceed virtual try-on with the body model and evaluate the design rendering. Import the final design to the dimensional cutting system for further producing.

The solution makes it possible to tailor according to the result of 3D scanning, which fully considers the daily activity so that the apparel can achieve a great balance between comfortability and a sense of beauty.

On top of that, this 3D solution enables companies to build its databases that contain the body data of customers so that customers can save the trouble of being tailored repeatedly. What’s more? With the expansion of the database, companies can make more precise size reckon according to the body size of customers, shortening the time of designing and producing greatly.

In conclusion, with the help of our intelligent 3D apparel customization solution, company can easily transit to intelligent manufacturing, improving the efficiency and reducing the cost.

WHY SCANTECH SOLUTION?

With SCANTECH iReal handheld 3D scanner, companies can achieve millimeter-level data instead of centimeter-level one measured by hand. Besides that, 3D scanning provides with full-scale body 3D model (including data that cannot be measured manually). The more comprehensive size companies have, the more precise apparel they can make.

iReal also makes it possible to proceed with non-contact 3D scanning, which is able to collect data of the whole body within 50 seconds. iReal also adopts the infrared VCSEL structured light, which brings a safe and comfortable 3D scanning experience.

Compared with traditional matrix body 3D scanner, iReal is much more portable for its 850g weight. Hence it is easy carrying, you can take it anywhere you want. It turns out to be cost-saving for companies because it is unnecessary to prepare 3D scanner for each store. They can even provide door to door tailoring service with iReal because it is easy to use even for novices.

Simultaneously, iReal is much more cost-effective for its price is only 1/10 to 1/3 of the price of a traditional 3D body scanner.

Simultaneously, iReal is much more cost-effective for its price is only 1/10 to 1/3 of the price of a traditional 3D body scanner.

The application of iReal in the garment industry is not limited to the apparel customization, it can also offer help to the formulation of standard size, virtual try-on and so on.

There are great differences between the body size of people from different regions. As a result, it is often the case that standard size may vary from country to country. iReal can contribute to the build of body database so that companies can study the difference of different customer group and produce more fitted apparel.

For the virtual try-on, the general solution right now is providing a standard model that shares similar basic body data with customers. However, in reality, people with the same height and weight may have totally different body sizes, meaning the standard model only provides limited reference value. With 3D scanner, companies can achieve a precise full-scale model, which is much more suitable for virtual try-on.

For the virtual try-on, the general solution right now is providing a standard model that shares similar basic body data with customers. However, in reality, people with the same height and weight may have totally different body sizes, meaning the standard model only provides limited reference value. With 3D scanner, companies can achieve a precise full-scale model, which is much more suitable for virtual try-on.

Though non-contact 3D body scanning only has history of 30 years, it has been widely applied to all kinds of areas of the design and study of human product. Apparel industry has been in the revolution of intelligent and flexible production, 3D scanning will have wider and deeper application with the development of technology.

For more 3D body scanning cases, please read: