Drinking water reverse osmosis water treatment plant China manufacture

Product description

RO AUGA offers complete mini reverse osmosis water purification plant, fully assembled on a single stainless steel skid. From pre-treatment to reverse osmosis systems to post-treatment and storage tanks, the package can readily produce high-quality water for many applications. We use high-quality components and take pride in the overall quality and reliability of our system. All systems are fully tested prior to shipment. We can produce different capacity, 250LPH, 500LPH, 1000LPH, 2000LPH. 500lph and 1000lph mini capacity is hot selling on the market. Customers praise the most and also the most commonly used product around the world. This 500lph/1000lph RO machine can handle different raw water with TDS below 2000ppm such as underground water, tap water, well water, deep water, borehole water.  Within the RO system, the TDS of produced water can reach 20-40 ppm, which can directly drink and meet the requirements of various industries with high water quality. This set of equipment is well configured to solve most of the water problems encountered in life such as heavy metals, particles, bacteria and so on. At the same time, the wheel of the machine is designed with the frame which is convenient for free movement.

Within the RO system, the TDS of produced water can reach 20-40 ppm, which can directly drink and meet the requirements of various industries with high water quality. This set of equipment is well configured to solve most of the water problems encountered in life such as heavy metals, particles, bacteria and so on. At the same time, the wheel of the machine is designed with the frame which is convenient for free movement.

Product benefit

Over 10 years of experience in reflected in our quality

Manufactured in China and Certified Facilities

Conservatively engineered for reliable, long term performance

Factory tested to ensure trouble-free operation

Stainless steel high pressure components, stainless steel pump

Microprocessor controlled operation

Product feature

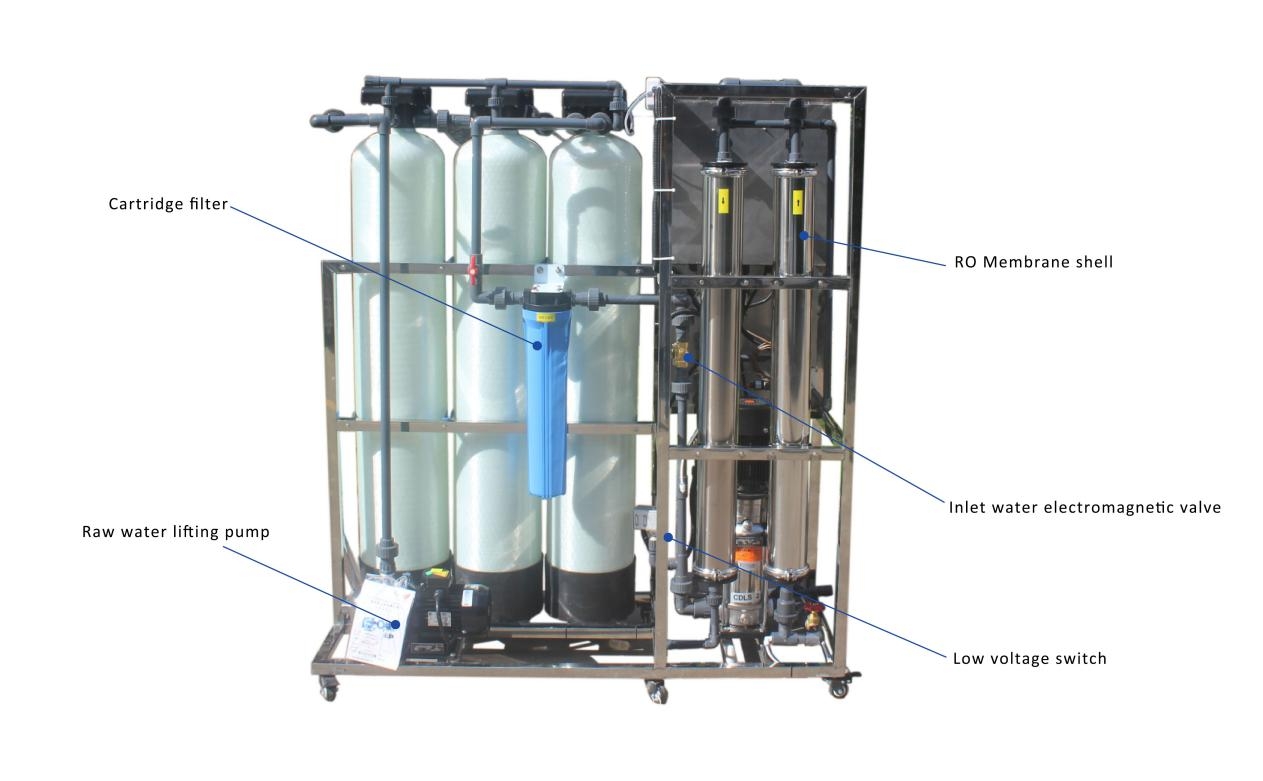

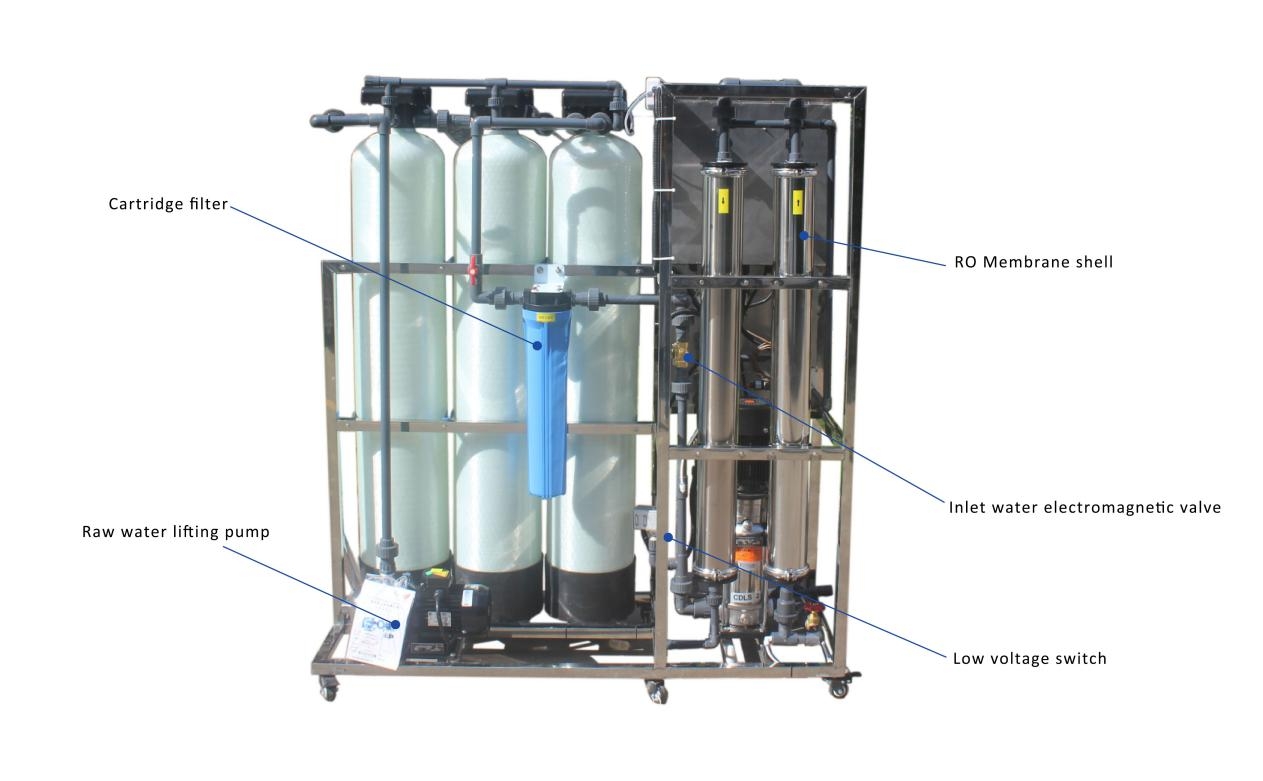

Here I am going to express details information about machine parts of 500lph RO.

500LPH RO machine is considered by many segments of part. They are such as-

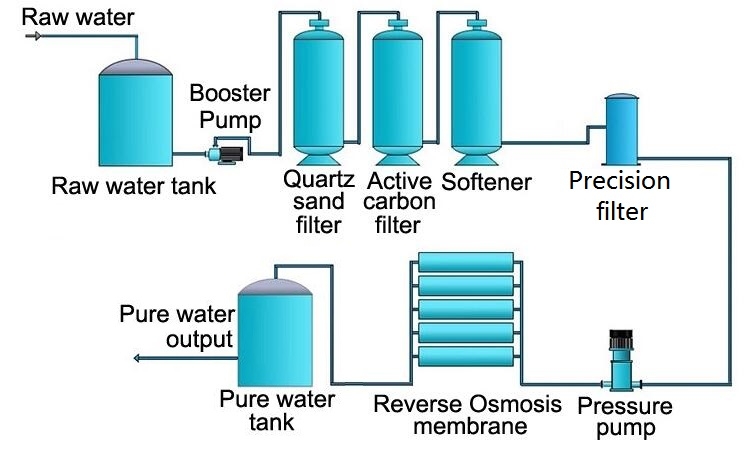

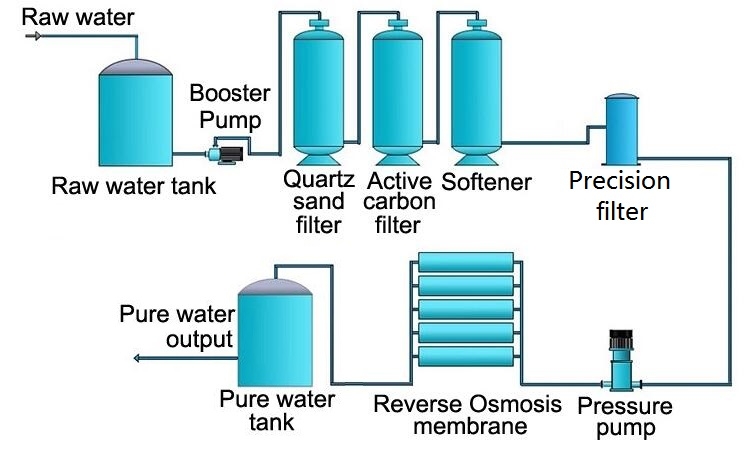

Raw water tanks, raw water pump, automatic sand filter, activated carbon filter, water softener, security filter, high pressure pump, RO membrane, RO water tank, precision filter.

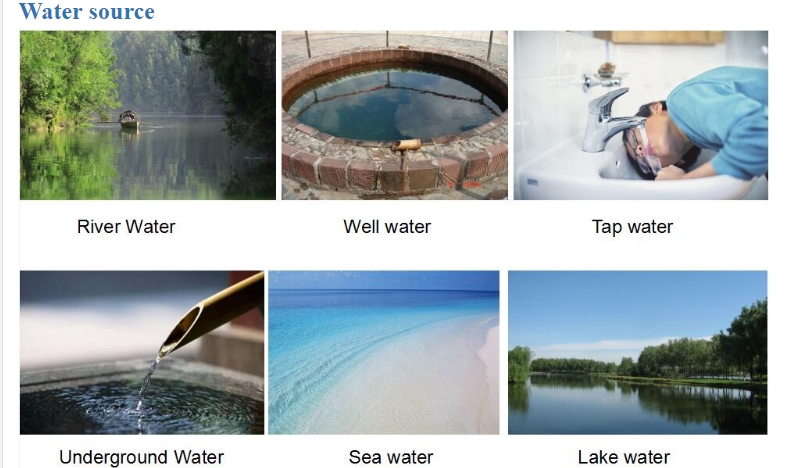

So the first thing is our raw water source it basically depends on buyer how the raw water will be taken, perhaps it will be tank or other source like tap water, well water, deep water etc. In fact The pressure of the original water pump is about 3-5 bar. It is made of 304/316 stainless steel. The famous brands are CNP and Grundfos.

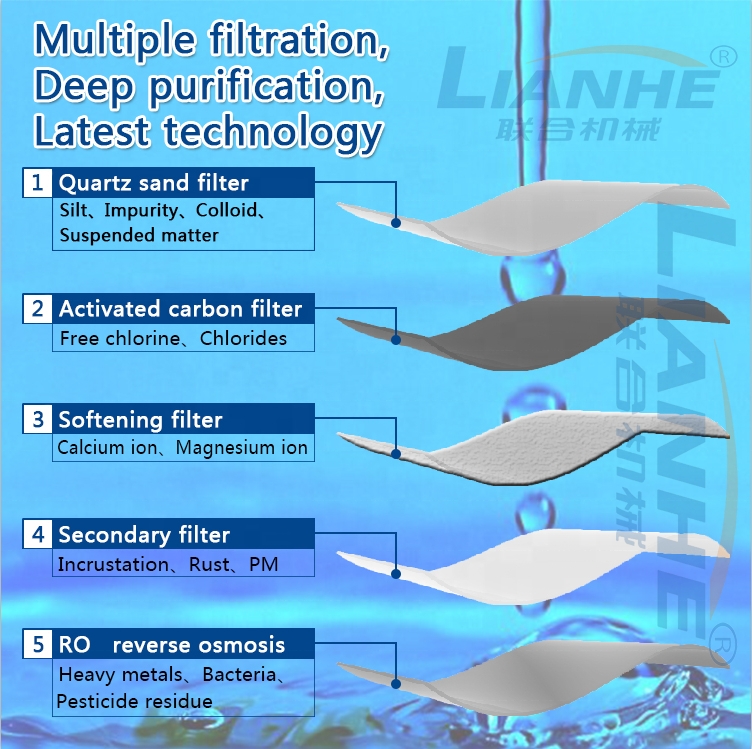

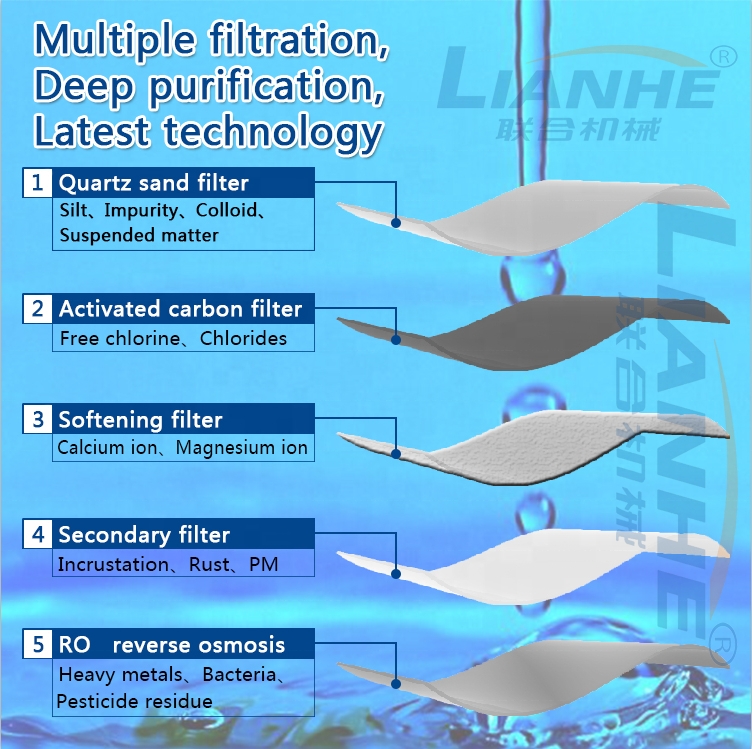

After then we will concentrate about raw water pump, this pump pull in the raw water from the source and flow to automatic sand filter. Before that we have to pour the relevant materials into 3 different Tanks of automatic sand filter, activated carbon filter and water softener. The main materials are quartz sand, activated carbon and resin.

With this sand filter there are another connection with activated carbon filter and then with water softener. So here sand filter remove colloid, turbidity, organic matter, suspended matter etc. On the hand remove harmful matter, color, organic matter, free chloride, etc. And lastly remove salts of calcium ion, magnesium that may form scale encrustations.

Then we will get Security filter which is used to filter small substances, often used for secondary filtration to ensure the accuracy of the filtered water. Afterwords,

There is a connection with high pressure pump, The function of the high pressure pump is to increase the pressure of reverse osmosis feed water. Reverse osmosis is a pressure-driven treatment. Increasing the inlet pressure improves both the product or reject efficiency and the quality of the product water (TDS).

Basically The high-pressure pump adopts the well-known brands of CNP and Grundfos. The model of materials is SS304 and SS316. This type of materials is produced by Stainless steel according to the ASTM standard of the United States.

This high pressure pump will flow the water to RO membrane that removes contaminants from water by using pressure to force water molecules through a semipermeable membrane.

Generally, Vontron and Dow membrane are the most popular RO membranes are used in RO systems. The 500LPH RO system is used by two pieces of RO membranes. The membrane material is Aromatic polyamide, which has excellent heat resistance and insulation properties.

From this RO membrane we can observe two path where one is for collecting pure water and another is for concentrate water. Eventually the last stage is Precision filter.

RO machine must-have precision filter for producing high-purified water. Its accuracy is 5µm and it can prevent viruses,a large number of organic particles, bacteria into RO membrane.

It is completely related on RO membrane so if we don’t use the precision filter then can be seen the RO membrane is going to be block. This is the fundamental working method of 500lph RO. Besides this, few responsibilities we have to do like-

1)In the RO precision filter is fitted with a PP filter element and have to put the RO membrane into the membrane housing with loaded.

2) We have to adjust the valve and set the time for each valve. Also the valve has 3 times to display such as filter time, rinse time and backwash time.

3)Supervision the equipment operation like need to make a record of data about water production, operating pressure, and water quality. Meanwhile we can observe the data from the flow meter, pressure gauge, and conductivity meter.

4)For the last action we should follow machine maintenance where we know of 500lph RO is automatic and convenient to understand. As example- The machine can be operated for a period of time to set the flushing time through an automatic valve.

5)For example, wash once every 3 days to achieve better use and lengthen the service life of the equipment.

Product application

Complete reverse osmosis water treatment plant widely used in laboratories, food factories, electroplating factories, pharmaceutical factories, electronics factories, paper mills, water factories. For the food industry, pure drinking water, beverages, beer, wine, health products. For the chemical industry, chemical recycling water, chemical products manufacturing, chemical fertilizer etc.

Within the RO system, the TDS of produced water can reach 20-40 ppm, which can directly drink and meet the requirements of various industries with high water quality. This set of equipment is well configured to solve most of the water problems encountered in life such as heavy metals, particles, bacteria and so on. At the same time, the wheel of the machine is designed with the frame which is convenient for free movement.

Within the RO system, the TDS of produced water can reach 20-40 ppm, which can directly drink and meet the requirements of various industries with high water quality. This set of equipment is well configured to solve most of the water problems encountered in life such as heavy metals, particles, bacteria and so on. At the same time, the wheel of the machine is designed with the frame which is convenient for free movement.